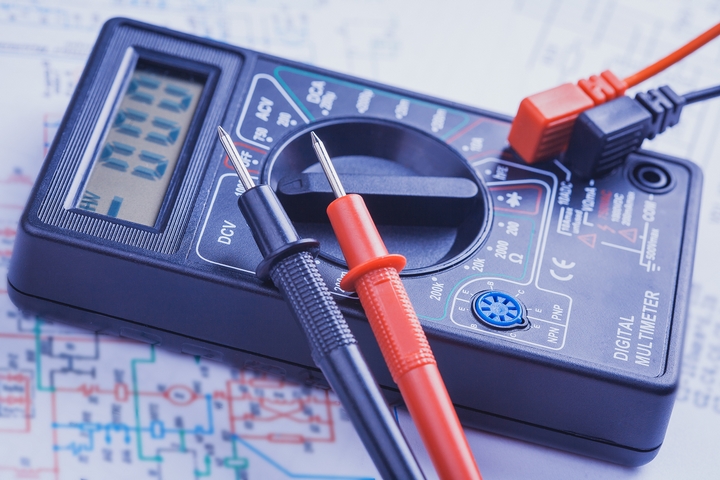

In measurement technology and metrology, calibration is the comparison of measurement values delivered by a device under test with those of a calibration standard of known accuracy. The increasing need for known accuracy and uncertainty and the need to have consistent and comparable standards internationally has led to the establishment of national laboratories. So when looking for a calibration service you can trust, you want to know that the results of their calibration have been accepted by outside organizations and are traceable to the internationally defined measurement unit.

1. Why you need to find time for regular calibration

Regular calibration might not be top of mind, but it is critical, as the accuracy of instruments measurements start to drop over time. You have to make sure the instruments don’t get ‘out of calibration’ and it is better to be proactive rather than wait until a problem arises. You will observe that the accuracy of major components of instruments like voltage references, current shunts and input dividers will start to shift over time. That being said, this shift is minor and wouldn’t affect the measurements if you maintain a good calibration schedule as it will find and correct the shift.

2. How often is ‘regular’ for calibrating instruments

Basically, there isn’t a ‘one-size-fits-all’ kind of an answer to this. Every instrument has different calibration frequency requirement. However, there are some general rules you can apply to help keep things in calibration.

3. Major projects and unforeseen accident

For example, if you have to carry out highly accurate measurements for a project, decide which instruments you will be using for the testing. Once you have the list of instruments, decide how you want to go about having them calibrated, and do not use them until the test. Keeping them on a ‘lock down’ until the testing phase begins will ensure that you get absolutely accurate results. Similarly, if something unexpected occurs during use, it is probably a good idea to seek calibration services. In the event that your instruments took a hit, like a sharp physical impact or if something knocked out the internal overload, you should have them calibration and also checked for integrity and general safety.

4. In-lab calibration

You have options when it comes to seeking calibration services. The most common way calibration services are performed is in-lab. This involved shipping or dropping off in person the instrument you need calibrated. Generally, the lab should be able to complete the service relatively quickly and you can expect to have the instrument returned to you within a few business days.

5. Onsite Calibration

Another flexible option is to have your instruments calibrated at your facility. Of course this can often be the most convenient course of action, but be aware that you’re going to have to pay for the premium service. In this case, you will work with an onsite coordinator to schedule the work to be performed when it works best for you. That being said, not everything can be calibration onside and you might have to consider each company’s policy when it comes to exclusions and minimum rates.

6. Managed Services

It is also possible that, if you have a variety of calibration service needs, you will have to work with multiple companies in order to have all your jobs completed. No single provider can provide services on every type of instrument. For this reason, a lots of calibration service providers develop a trusted network of approved vendors to exchange resources and clients. If your needs are extensive and varied, finding a provider that offers this can help you consolidate your suppliers and reduce your costs.